In today’s constantly advancing world, LiDAR technology is reaching a performance level that allows for results with high point densities, a large number of echoes recorded per pulse, great precision, and a high capacity to distinguish different objects. Simultaneously, LiDAR sensors have become more affordable, lighter, more precise, and versatile. This evolution has opened opportunities for companies worldwide to enter the data capture business by incorporating this cutting-edge technology, whether from aerial vehicles (manned or unmanned), automobiles, backpacks, or even handheld devices.

Hardware and software have evolved alongside sensors, allowing the processing and editing of tens of millions of points on a standard CAD, as well as online real-time visualization of data on remote servers or in the cloud, something unthinkable not long ago. We now have access to an increasing amount of higher quality geospatial data, while other parameters such as update frequency and available data types are also expanding.

With the advent of LiDAR sensors installed on increasingly affordable drones, the market has seen a shift from a few specialized companies to the emergence of hundreds of new players. However, the ease of investing in data capture hardware does not always guarantee the transformation of that data into valuable products. Activities such as processing and classifying LiDAR data still require significant effort and can become a bottleneck in the production chain. On the other hand, the availability of geospatial data has solidified previously emerging applications and facilitated the emergence of new ones.

Thus, in addition to products like digital elevation models, contour lines, orthophotos, and mosaics, the market demands others such as 3D vector mapping, customized distance reports, simulation of power line positions under different environmental conditions, 3D models, digital twins, etc. Exploiting these data requires efficient systems for storage, quality control, and publication on geoportals, as well as the ability to analyze them to obtain complex derivative products in increasingly shorter times.

Increases in computing power have enabled the application of algorithms for more massive and efficient data processing. The use of AI models with their learning and pattern recognition capabilities is facilitating the automation of tasks. However, there are still processes that require significant effort, both in labor-intensive interactive editing tasks and in managing these tasks, heuristically defining algorithm parameters, and ensuring quality control of all processes, manual or automatic, to achieve final products with near 100% reliability.

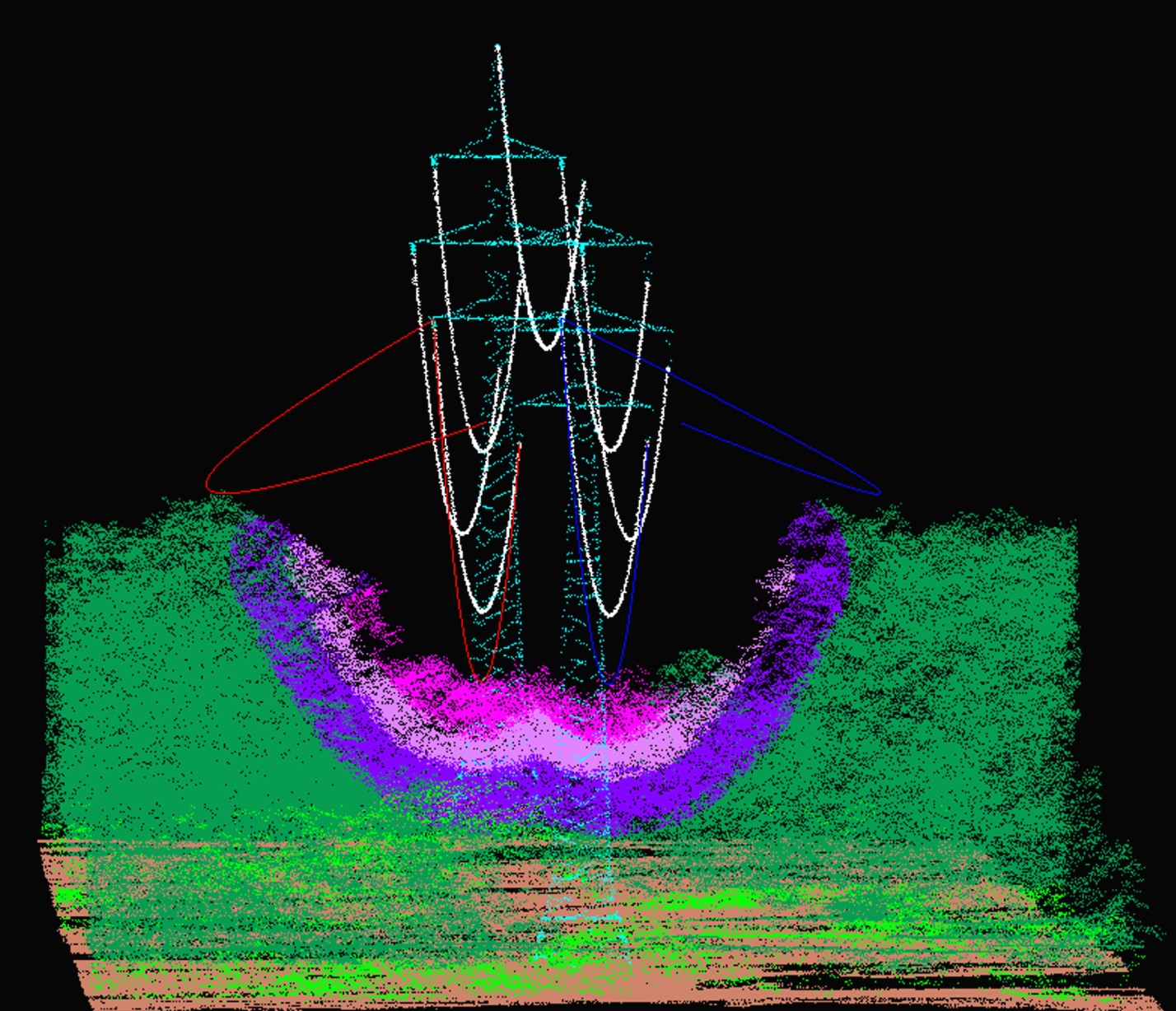

The market is increasingly demanding and seeks greater utilization of data and more complex derivative products. For example, the purpose of precise modeling of a watershed or snow cover in high mountains is, among other things, to conduct flood risk analysis and prevent catastrophic situations. It is not enough to capture the geometry of a high-voltage power line and determine the distances to nearby vegetation; its behavior must also be modeled against atmospheric phenomena such as temperature variations or wind. Thanks to forest inventory work using LiDAR, tree mass can be determined to create fuel model maps for wildfire prevention and prediction, emissions, etc.

Geospatial data capture work is often subject to temporal peaks due to client-imposed deadlines, climatic and weather conditions, and other external circumstances such as flight permits, administrative delays, etc. Even the largest companies might be forced to have an oversized structure in terms of both technical and human resources. For small companies trying to take advantage of the latest sensor technology opportunities, having such processing capacity can pose a barrier to entry into this market.

This is where the importance of having specialized partners in LiDAR data processing, such as DIELMO 3D, comes in. With over twenty years in the sector, DIELMO 3D has developed advanced solutions for the processing, management, and publication of geospatial data and has a robust and flexible processing infrastructure, high production capacity, and service customization. By working with a significant range of clients, they can distribute the workload more efficiently over time, allowing data capture companies to focus exclusively on their business without worrying about the complexities of subsequent processing.

DIELMO 3D’s investment in R&D&I not only guarantees high production capacity but has also been used to develop custom solutions for highly specialized products such as distance studies of vegetation to power lines, railways, custom report preparation, power line modeling under different environmental conditions using PLSCADD or their own alternative tool, tree measurement for forest inventory, AI model development, web geoportals for visual infrastructure inspection management, geoportals for public agencies, etc.

Collaborating with experts in LiDAR data processing allows data capture companies to concentrate on their capture activity more efficiently from the moment they acquire LiDAR equipment, without worrying about processing and obtaining very specific products. For companies with significant experience and resources that already have a data processing structure, this collaboration provides flexibility and the peace of mind of being protected against temporary work peaks or unforeseen events, keeping their processing structure within efficient limits. The technological capability and adaptability of these partners allow them to develop tailored solutions, establishing solid strategic alliances.

While artificial intelligence and automated processes offer many advantages, some tasks still require human intervention to ensure the precision and reliability of the final products. DIELMO 3D combines the best of both worlds: it uses AI-based automation to optimize processes but also brings the experience and production capacity necessary to control and improve results. This ensures that the final products are accurate and high-quality, avoiding the problems that can arise when these advanced tools are operated by those without adequate experience. In this way, DIELMO 3D helps maintain long-term customer trust, ensuring their satisfaction and loyalty in a competitive market.